Insulated Metal Panels

U-Build Steel Buildings offers the exceptional Artspan Insulated Metal Panel as an option for all U-Build Rigid Frame Steel Buildings, or ordered separately. These panels are available in a variety of colors and profiles. They can be installed as exterior walls, interior walls, and high-performance roofs; including cold storage applications.

These panels are naturally well suited for institutional, commercial, and industrial projects of all sizes and complexity, as they’re helpful for achieving energy code. You’ll also find these panels suitable for any building that requires temperature regulation such as in the agricultural sector for vegetable/potato storage buildings, and for heated shops.

The Benefits of our IMP's

1 Superior thermal values

The superior thermal values of our IMP's make increasing thermal performance across climate zones easy to achieve for both walls and roofs.

2 Quick and easy installation

Installation of insulated metal panels is quick and easy, allowing the building to be completely enclosed in a fraction of the time compared to conventional wall assemblies. This is ideal for building in any season, and you'll save money in labour costs.

3 Save footprint and meet building codes

You'll be able to achieve your buildings required energy codes, while saving space on the overall footprint of the building.

Artspan Inc. Insulated Metal Panels Specifications and Technical information

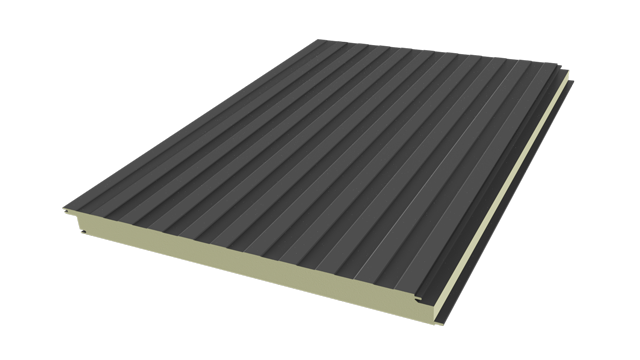

Horizon Wall panels are produced with a standard Mesa profiled steel face with a Smooth (SM) or Light Embossed finish (LE). Provides economical panels for industrial and commercial walls with added strength from a double Mesa profile for long panel lengths.

- COVERAGE WIDTH: 42” (1067mm)

- PANEL LENGTHS: 8’ to 52’ (2438mm to 15850mm)

- PROFILE: Mesa

- EXTERIOR FACE: 22ga, 24ga, or 26ga galvanized G-90 (Z275) pre-painted steel

- INTERIOR FACE: 22ga, 24ga, or 26ga galvanized G-90 (Z275) pre-painted steel

- AVAILABLE FINISH: Smooth, Light Emboss

| THICKNESS | 2” | 3” | 4” | 5” | 6” |

| EFFECTIVE R-VALUE* | 16.67 | 25 | 33.33 | 41.67 | 50 |

INTERIOR FACE 26ga Mesa profile in smooth or light embossed galvanized G-90 (Z275) pre painted steel in Regal White. Other gauge options available.

* Thermal testing in accordance with ASTM C1363 and ASTM C518.

Standard Exterior Colours

Premium Exterior Colours

- Colours may not appear exactly as shown above and may vary slightly.

- Please confirm prior to specifying, estimating or ordering.

- Final colour selection should be made from a steel colour sample.

- Colour selection may be subject to availability.

- Custom colours available upon request.

Series: Edge, Horizon.

Profile: Mesa or Smooth.

Gauge: 26 ga or heavier.

Finished: Embossed or Smooth.

| Panel Thickness | Design Criteria | 4' Allowable Loads (PSF) | 5' Allowable Loads (PSF) | 6' Allowable Loads (PSF) | 7' Allowable Loads (PSF) | 8' Allowable Loads (PSF) | 9' Allowable Loads (PSF) | 10' Allowable Loads (PSF) | 11' Allowable Loads (PSF) | 12' Allowable Loads (PSF) | 13' Allowable Loads (PSF) | 14' Allowable Loads (PSF) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2" Thick (See Table Note #3) |

Bending/Shear | 93 | 59 | 41 | 30 | 23 | 18 | 15 | 12 | 10 | ||

| 2" Thick | Deflection (L/180) | 47 | 41 | 33 | 27 | 22 | 19 | 16 | 14 | 12 | ||

| 2" Thick | Connection | 42 | 35 | 33 | 26 | 22 | 19 | 16 | 15 | 13 | ||

| 3" Thick | Bending/Shear | 126 | 101 | 84 | 68 | 52 | 41 | 33 | 27 | 23 | ||

| 3" Thick | Deflection (L/180) | 94 | 77 | 68 | 58 | 34 | 32 | 29 | 19 | 17 | ||

| 3" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | ||

| 4" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 4" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 4" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 5" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 5" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 5" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 6" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 6" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 6" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

TABLE NOTES:

1) Allowable loads were derived from tests conducted in accordance with ASTM E1592 and ASTM E72.

2) Allowable loads are calculated with a factor of safety of 2.0 for bending and shear.

3) Connection strengths reflect a standard fastener pattern - with two (2) 1/4" - 14 self drilling screw into minimum 14ga substrate. Other substrates must be designed separately. 2" wall panel utilize a flat clip. All other thicknesses utilize an angle clip.

4) Fastener capacity is based on manufacturer pullout/pullover data and are calculated with a safety factor of 3.0.

5) Allowable loads assume a minimum bearing of 2".

6) Thermal Effects were not considered in analysis.

7) The structural capacity of the supporting members were not considered.

8) Bending/Shear and Deflection for 5" and 6" panels based on 4" capacity.

PANEL WEIGHTS (PSF)

| Panel Thickness (in.) |

Panel Width (in.) |

26/26 Steel Gauge (Facer/Liner) | 24/26 Steel Gauge (Facer/Liner) | 22/26 Steel Gauge (Facer/Liner) | 26/24 Steel Gauge (Facer/Liner) | 24/24 Steel Gauge (Facer/Liner) | 22/24 Steel Gauge (Facer/Liner) | 26/22 Steel Gauge (Facer/Liner) | 24/22 Steel Gauge (Facer/Liner) | 22/22 Steel Gauge (Facer/Liner) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 2.23 | 2.48 | 2.73 | 2.48 | 2.73 | 2.98 | 2.76 | 2.98 | 3.23 |

| 3 | 42 | 2.44 | 2.69 | 2.94 | 2.69 | 2.94 | 3.19 | 2.94 | 3.19 | 3.44 |

| 4 | 42 | 2.65 | 2.90 | 3.15 | 2.90 | 3.15 | 3.40 | 3.15 | 3.40 | 3.65 |

| 5 | 42 | 2.85 | 3.10 | 3.35 | 3.10 | 3.35 | 3.60 | 3.35 | 3.60 | 3.85 |

| 6 | 42 | 3.06 | 3.31 | 3.56 | 3.31 | 3.56 | 3.81 | 3.56 | 3.81 | 4.06 |

MAXIMUM PANEL LENGTHS BASED ON COLOUR (FT).

| Panel Thickness (in.) | Panel Width (in.) | Light Edge 22ga Wall* | Medium Edge 22ga Wall* | Dark Edge 22ga Wall* | Light Horizon 26ga/26ga Wall | Medium Horizon 26ga/26ga Wall | Dark Horizon 26ga/26ga Wall | Light Skyline 24ga/26ga Roof | Medium Skyline 24ga/26ga Roof | Dark Skyline 24ga/26ga Roof |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 25' | 25' | 20' | 38' | 25' | 16' | 47' | 36' | 24' |

| 3 | 42 | 30' | 30' | 20' | 45' | 35' | 25' | 50' | 38' | 30' |

| 4 | 42 | 30' | 30' | 25' | 50' | 38' | 28' | 52' | 41' | 32' |

| 5 | 42 | 32' | 30' | 25' | 52' | 41' | 30' | 52' | 44' | 34' |

| 6 | 42 | 32' | 30' | 25' | 52' | 44' | 32' | 52' | 47' | 36' |

*Smooth or Embossed

Light = Regal White

Medium = Sierra Tan, Parchment, Silver Metallic

Dark = All others

Based on 5' support spacing for walls & 4' support spacing for roofs

*Smooth or Embossed

Subject to change without notice. Please refer to our website, www.artspaninc.com for current information.

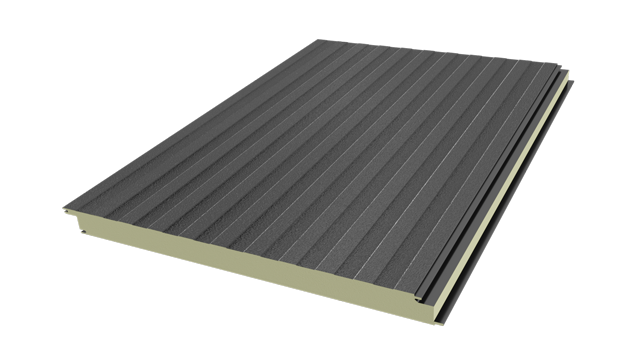

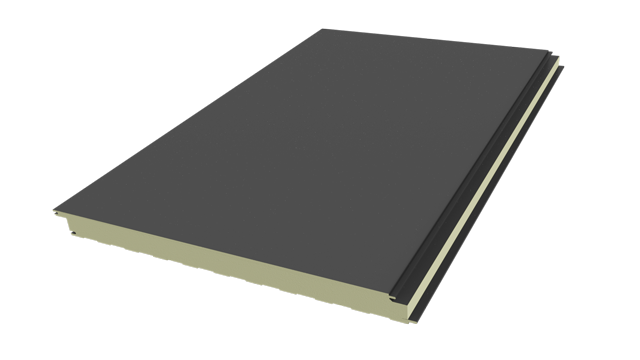

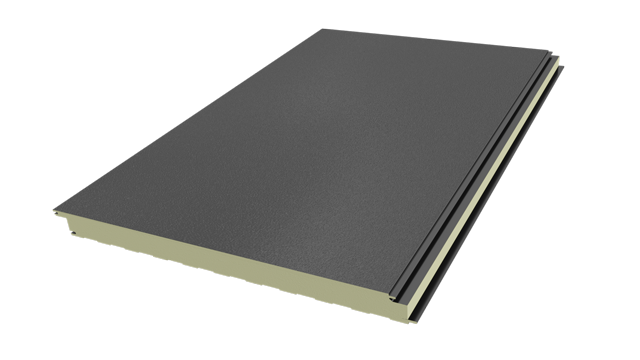

Leading Edge LE wall panels are produced with a standard flat steel face with no profile, offering a clean look to the exterior. These panels are available with the following exterior finishes:

- SMOOTH (SM): Provides flat, smooth face.

- LIGHT EMBOSSED (LE): Provides added subtle visual texture to a flat panel.

Coverage Width: 42” (1067mm)

Panel Lengths: 8’ to 32’ (2438mm to 9754mm) based on colour selection

Profile: Flat

Exterior Face: 22ga galvanized G-90 (Z275) pre-painted steel

Interior Face: 22ga, 24ga, or 26ga galvanized G-90 (Z275) pre-painted steel

Available Finish: Smooth, Light Emboss

| THICKNESS | 2” | 3” | 4” | 5” | 6” |

| EFFECTIVE R-VALUE* | 16.67 | 25 | 33.33 | 41.67 | 50 |

INTERIOR FACE 26ga Mesa profile in smooth or Light Embossed galvanized G-90 (Z275) pre painted steel in Regal White. Other gauge options available.

* Thermal testing in accordance with ASTM C1363 and ASTM C518.

Standard Colours

Premium Colours

- Colours may not appear exactly as shown above and may vary slightly.

- Please confirm prior to specifying, estimating or ordering.

- Final colour selection should be made from a steel colour sample.

- Colour selection may be subject to availability.

- Custom colours available upon request.

Series: Edge, Horizon.

Profile: Mesa or Smooth.

Gauge: 26 ga or heavier.

Finished: Embossed or Smooth.

| Panel Thickness | Design Criteria | 4' Allowable Loads (PSF) | 5' Allowable Loads (PSF) | 6' Allowable Loads (PSF) | 7' Allowable Loads (PSF) | 8' Allowable Loads (PSF) | 9' Allowable Loads (PSF) | 10' Allowable Loads (PSF) | 11' Allowable Loads (PSF) | 12' Allowable Loads (PSF) | 13' Allowable Loads (PSF) | 14' Allowable Loads (PSF) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2" Thick (See Table Note #3) |

Bending/Shear | 93 | 59 | 41 | 30 | 23 | 18 | 15 | 12 | 10 | ||

| 2" Thick | Deflection (L/180) | 47 | 41 | 33 | 27 | 22 | 19 | 16 | 14 | 12 | ||

| 2" Thick | Connection | 42 | 35 | 33 | 26 | 22 | 19 | 16 | 15 | 13 | ||

| 3" Thick | Bending/Shear | 126 | 101 | 84 | 68 | 52 | 41 | 33 | 27 | 23 | ||

| 3" Thick | Deflection (L/180) | 94 | 77 | 68 | 58 | 34 | 32 | 29 | 19 | 17 | ||

| 3" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | ||

| 4" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 4" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 4" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 5" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 5" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 5" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 6" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 6" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 6" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

TABLE NOTES:

1) Allowable loads were derived from tests conducted in accordance with ASTM E1592 and ASTM E72.

2) Allowable loads are calculated with a factor of safety of 2.0 for bending and shear.

3) Connection strengths reflect a standard fastener pattern - with two (2) 1/4" - 14 self drilling screw into minimum 14ga substrate. Other substrates must be designed separately. 2" wall panel utilize a flat clip. All other thicknesses utilize an angle clip.

4) Fastener capacity is based on manufacturer pullout/pullover data and are calculated with a safety factor of 3.0.

5) Allowable loads assume a minimum bearing of 2".

6) Thermal Effects were not considered in analysis.

7) The structural capacity of the supporting members were not considered.

8) Bending/Shear and Deflection for 5" and 6" panels based on 4" capacity.

PANEL WEIGHTS (PSF)

| Panel Thickness (in.) |

Panel Width (in.) |

26/26 Steel Gauge (Facer/Liner) | 24/26 Steel Gauge (Facer/Liner) | 22/26 Steel Gauge (Facer/Liner) | 26/24 Steel Gauge (Facer/Liner) | 24/24 Steel Gauge (Facer/Liner) | 22/24 Steel Gauge (Facer/Liner) | 26/22 Steel Gauge (Facer/Liner) | 24/22 Steel Gauge (Facer/Liner) | 22/22 Steel Gauge (Facer/Liner) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 2.23 | 2.48 | 2.73 | 2.48 | 2.73 | 2.98 | 2.76 | 2.98 | 3.23 |

| 3 | 42 | 2.44 | 2.69 | 2.94 | 2.69 | 2.94 | 3.19 | 2.94 | 3.19 | 3.44 |

| 4 | 42 | 2.65 | 2.90 | 3.15 | 2.90 | 3.15 | 3.40 | 3.15 | 3.40 | 3.65 |

| 5 | 42 | 2.85 | 3.10 | 3.35 | 3.10 | 3.35 | 3.60 | 3.35 | 3.60 | 3.85 |

| 6 | 42 | 3.06 | 3.31 | 3.56 | 3.31 | 3.56 | 3.81 | 3.56 | 3.81 | 4.06 |

MAXIMUM PANEL LENGTHS BASED ON COLOUR (FT).

| Panel Thickness (in.) | Panel Width (in.) | Light Edge 22ga Wall* | Medium Edge 22ga Wall* | Dark Edge 22ga Wall* | Light Horizon 26ga/26ga Wall | Medium Horizon 26ga/26ga Wall | Dark Horizon 26ga/26ga Wall | Light Skyline 24ga/26ga Roof | Medium Skyline 24ga/26ga Roof | Dark Skyline 24ga/26ga Roof |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 25' | 25' | 20' | 38' | 25' | 16' | 47' | 36' | 24' |

| 3 | 42 | 30' | 30' | 20' | 45' | 35' | 25' | 50' | 38' | 30' |

| 4 | 42 | 30' | 30' | 25' | 50' | 38' | 28' | 52' | 41' | 32' |

| 5 | 42 | 32' | 30' | 25' | 52' | 41' | 30' | 52' | 44' | 34' |

| 6 | 42 | 32' | 30' | 25' | 52' | 44' | 32' | 52' | 47' | 36' |

*Smooth or Embossed

Light = Regal White

Medium = Sierra Tan, Parchment, Silver Metallic

Dark = All others

Based on 5' support spacing for walls & 4' support spacing for roofs

*Smooth or Embossed

Subject to change without notice. Please refer to our website, www.artspaninc.com for current information.

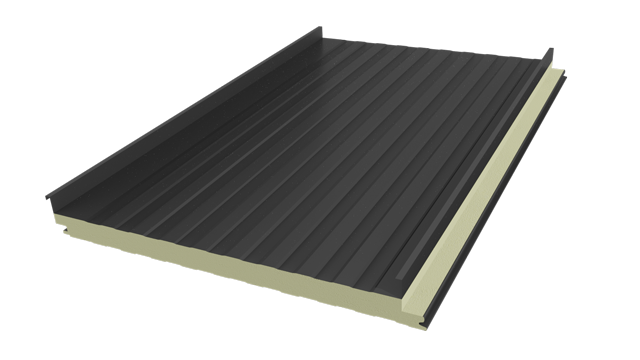

Skyline Roof panels are produced with a standard Mesa profiled non-embossed smooth steel face. Provides economical roof panels for industrial and commercial projects. 2” Standing seam is mechanically folded and incorporates a hidden fastened clip.

Coverage Width: 42” (1067mm)

Panel Lengths: 10’ to 52’ (3048mm to 15850mm)

Profile: Mesa

Exterior Face: 22ga, 24ga, or 26ga galvanized G-90 (Z275) pre-painted steel

Interior Face: 22ga, 24ga, or 26ga galvanized G-90 (Z275) pre-painted steel

Available Finish: Smooth, Light Emboss (Interior)

| THICKNESS | 2” | 3” | 4” | 5” | 6” |

| EFFECTIVE R-VALUE* | 16.67 | 25.00 | 33.33 | 41.67 | 50 |

INTERIOR FACE 26ga Mesa profile in smooth or Light Embossed galvanized G-90 (Z275) pre painted steel in Regal White. Other gauge options available.

* Thermal testing in accordance with ASTM C1363 and ASTM C518.

Standard Colours

Premium Colours

- Colours may not appear exactly as shown above and may vary slightly.

- Please confirm prior to specifying, estimating or ordering.

- Final colour selection should be made from a steel colour sample.

- Colour selection may be subject to availability.

- Custom colours available upon request.

Series: Skyline.

Profile: Mesa.

Gauge: 26 ga or heavier.

Finished: Smooth.

| Panel Thickness | Design Criteria | 2' Allowable Loads (PSF) | 3' Allowable Loads (PSF) | 4' Allowable Loads (PSF) | 5' Allowable Loads (PSF) | 6' Allowable Loads (PSF) | 7' Allowable Loads (PSF) | 8' Allowable Loads (PSF) |

|---|---|---|---|---|---|---|---|---|

| 2" Thick | Bending/Shear | 192 | 128 | 96 | 77 | 64 | 49 | 38 |

| 2" Thick | Deflection (L/240) | 58 | 53 | 48 | 43 | 36 | 29 | 24 |

| 2" Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

| 3" Thick | Bending/Shear | 192 | 128 | 96 | 77 | 64 | 49 | 38 |

| 3" Thick | Deflection (L/240) | 58 | 53 | 48 | 43 | 36 | 29 | 24 |

| 3" Thick | Connection | 64 | 44 | 33 | 26 | 22 | 19 | 16 |

| 4" Thick | Bending/Shear | 291 | 224 | 168 | 134 | 112 | 96 | 84 |

| 4" Thick | Deflection (L/240) | 98 | 95 | 92 | 90 | 76 | 63 | 53 |

| 4" Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

| 5" Thick | Bending/Shear | 317 | 286 | 215 | 172 | 143 | 123 | 107 |

| 5" Thick | Deflection (L/240) | 108 | 102 | 96 | 90 | 83 | 70 | 58 |

| 5" Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

| 6" Thick | Bending/Shear | 349 | 312 | 248 | 199 | 166 | 142 | 124 |

| 6" Thick | Deflection (L/240) | 110 | 110 | 109 | 109 | 108 | 92 | 77 |

| 6" Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

TABLE NOTES:

1. Allowable loads were derived from tests conducted in accordance with ASTM E1592 and ASTM E72.

2. Allowable loads are calculated with a factor of safety of 2.0 for bending and shear.

3. Connection strengths reflect a standard fastener pattern - with two (2) 1/4" - 14 self drilling screw into minimum 14ga substrate. Other substrates must be designed separately.

4. Fastener capacity is based on manufacturer pullout/pullover data and are calculated with a safety factor of 3.0.

5. Allowable loads assume a minimum bearing of 2".

6. Thermal Effects were not considered in analysis.

7. The structural capacity of the supporting members were not considered.

PANEL WEIGHTS (PSF)

| Panel Thickness (in.) |

Panel Width (in.) |

26/26 Steel Gauge (Facer/Liner) | 24/26 Steel Gauge (Facer/Liner) | 22/26 Steel Gauge (Facer/Liner) | 26/24 Steel Gauge (Facer/Liner) | 24/24 Steel Gauge (Facer/Liner) | 22/24 Steel Gauge (Facer/Liner) | 26/22 Steel Gauge (Facer/Liner) | 24/22 Steel Gauge (Facer/Liner) | 22/22 Steel Gauge (Facer/Liner) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 2.23 | 2.48 | 2.73 | 2.48 | 2.73 | 2.98 | 2.76 | 2.98 | 3.23 |

| 3 | 42 | 2.44 | 2.69 | 2.94 | 2.69 | 2.94 | 3.19 | 2.94 | 3.19 | 3.44 |

| 4 | 42 | 2.65 | 2.90 | 3.15 | 2.90 | 3.15 | 3.40 | 3.15 | 3.40 | 3.65 |

| 5 | 42 | 2.85 | 3.10 | 3.35 | 3.10 | 3.35 | 3.60 | 3.35 | 3.60 | 3.85 |

| 6 | 42 | 3.06 | 3.31 | 3.56 | 3.31 | 3.56 | 3.81 | 3.56 | 3.81 | 4.06 |

MAXIMUM PANEL LENGTHS BASED ON COLOUR (FT).

| Panel Thickness (in.) | Panel Width (in.) | Light Edge 22ga Wall* | Medium Edge 22ga Wall* | Dark Edge 22ga Wall* | Light Horizon 26ga/26ga Wall | Medium Horizon 26ga/26ga Wall | Dark Horizon 26ga/26ga Wall | Light Skyline 24ga/26ga Roof | Medium Skyline 24ga/26ga Roof | Dark Skyline 24ga/26ga Roof |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 25' | 25' | 20' | 38' | 25' | 16' | 47' | 36' | 24' |

| 3 | 42 | 30' | 30' | 20' | 45' | 35' | 25' | 50' | 38' | 30' |

| 4 | 42 | 30' | 30' | 25' | 50' | 38' | 28' | 52' | 41' | 32' |

| 5 | 42 | 32' | 30' | 25' | 52' | 41' | 30' | 52' | 44' | 34' |

| 6 | 42 | 32' | 30' | 25' | 52' | 44' | 32' | 52' | 47' | 36' |

*Smooth or Embossed

Light = Regal White

Medium = Sierra Tan, Parchment, Silver Metallic

Dark = All others

Based on 5' support spacing for walls & 4' support spacing for roofs

*Smooth or Embossed

Subject to change without notice. Please refer to our website, www.artspaninc.com for current information.